Metalworking

Metalworking Manufacturing

Processing Solutions

Equipped with Multiple Imported Equipment

CNC Machining

Utilizing cutting-edge CNC technology to precisely craft every product, taking pride in impeccable precision and stable quality, ensuring every customer can trust our professional services, obtaining reliable high-performance solutions

CNC Turning and Milling Composite Machining

Medical Automotive Bicycle Hand Tools Pneumatic Tools Precision Screwdrivers Door Locks Air Compressor Components Pneumatic Pump Components World’s Top Three Spray Gun Components and Accessories

Components for American Water Companies

Imported Processing Equipment

4-Axis Machining 4.5-Axis Machining

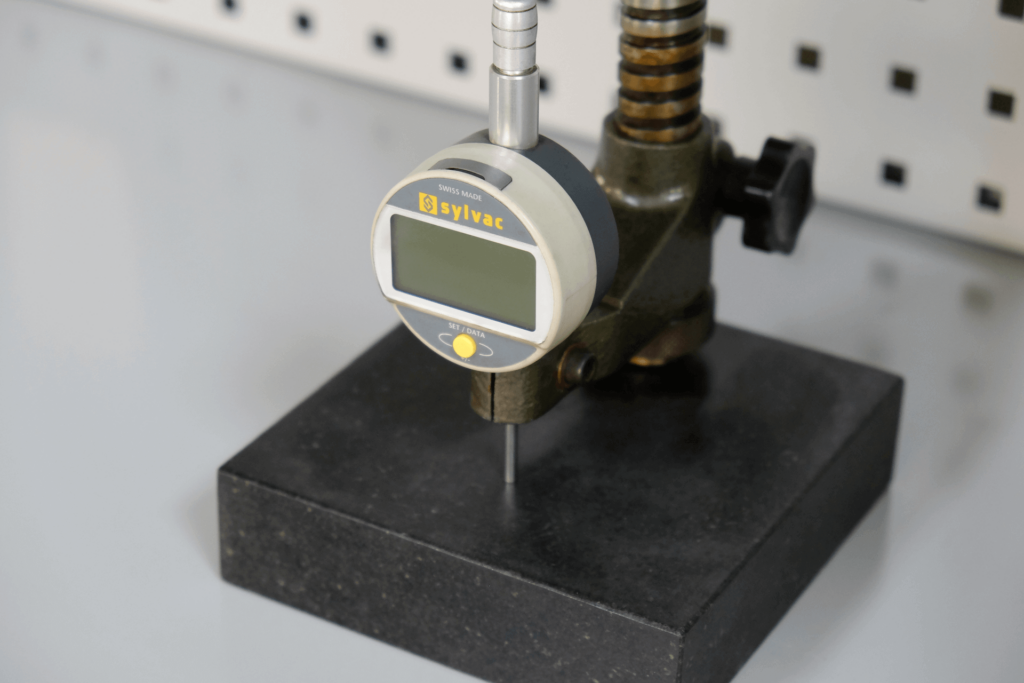

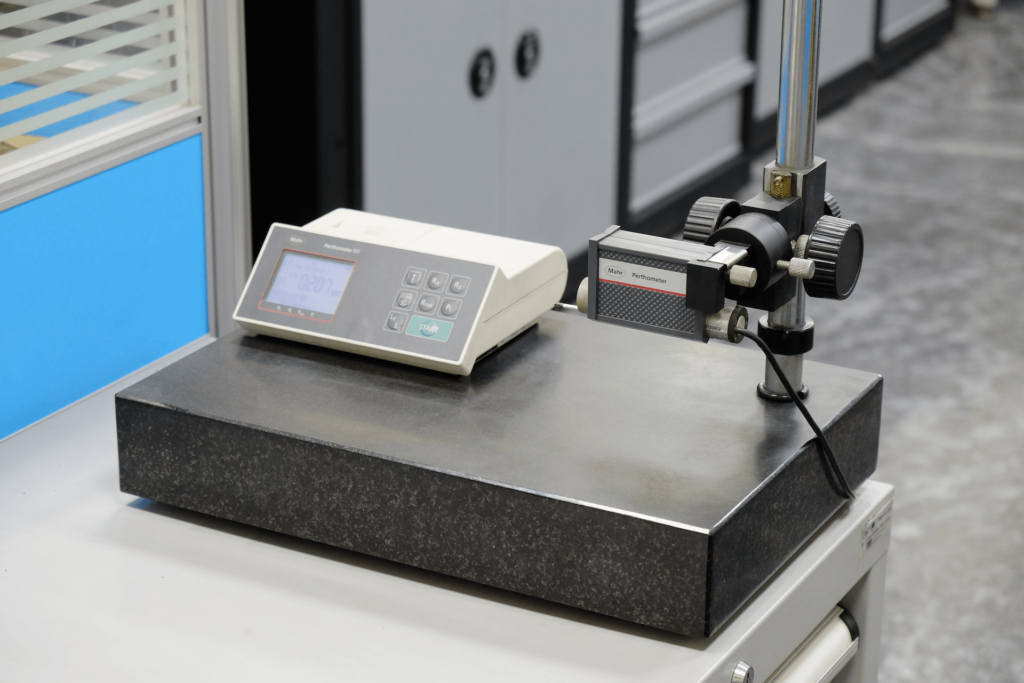

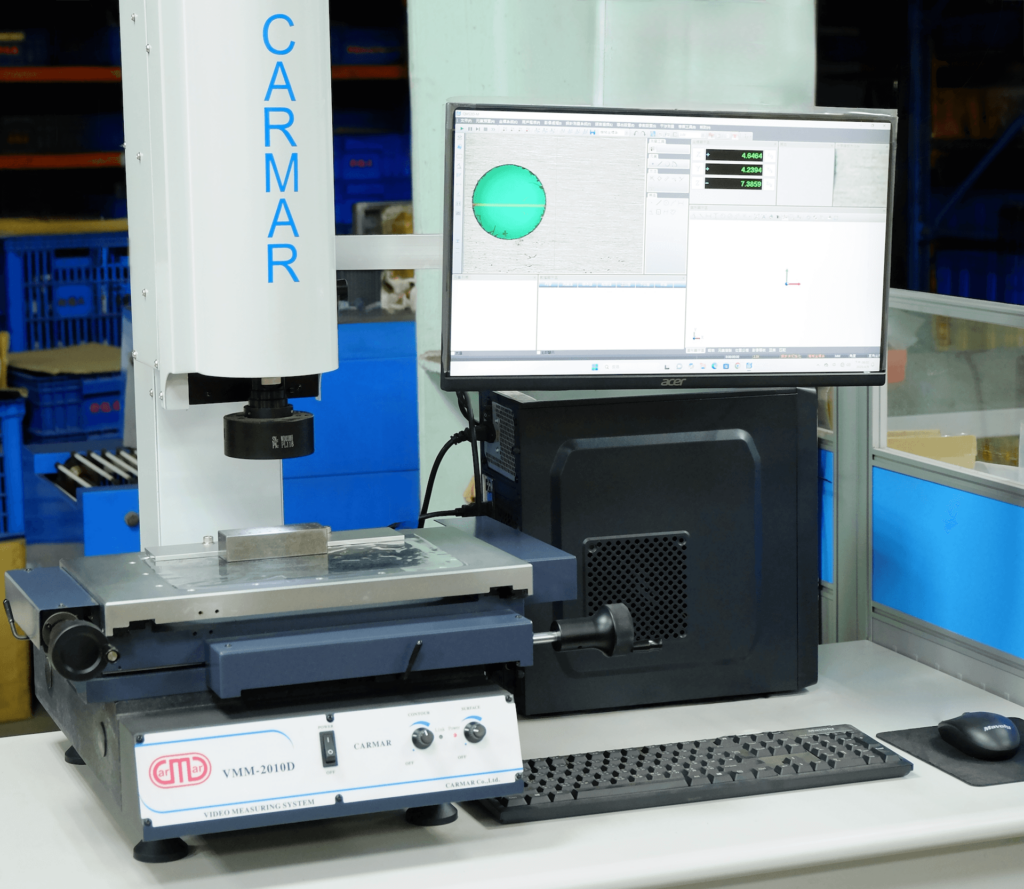

Inspection Equipment

Quality Testing

Pneumatic

Medical

Automotive

Door Locks

Hand Tools

Bicycle

Our Advantages

Serving Top Three Spray Gun Brands

Providing Hardware Components and Peripheral Tool Manufacturing

Pneumatic Hardware Tool Experience

Nearly Thirty Years of Pneumatic Tool Processing

Mobile Repair Tool Brand Collaboration

ODM Contract Design Precision Screwdrivers

Various Metal Processing Angles

Multi-Axis CNC Manufacturing to Meet Customer Requirements

Success Stories

Our processed products are sold to retail markets in Taiwan, United States, Japan, India, South Korea, Thailand, Malaysia, Australia, and Europe

Testing Instruments

Equipped with a series of advanced testing instruments capable of precisely measuring product dimensions, shape, hardness, and surface quality, and possessing thread gauges of various sizes to ensure every product meets customer requirements and international standards

Service Process

Providing Efficient Service Experience

1

STEP

Requirement Confirmation

Requirement Analysis

2

STEP

3d Prototyping and Quotation

Design Quotation

Provide product design solutions or customized solutions based on requirements, and submit quotations and schedules

3

STEP

Manufacturing and Processing

Manufacturing Processing

Utilizing precision equipment for processing and quality inspection, ensuring high-quality manufacturing

4

STEP

Packaging and Delivery

Packaging Delivery

Safely packaging products, arranging global logistics, ensuring timely delivery to customers

5

STEP

After-Sales Service

After-Sales Support

Providing technical support, product and logistics parts distribution, strengthening long-term partnerships

Reviews

Posted onTrustindex verifies that the original source of the review is Google. Posted onTrustindex verifies that the original source of the review is Google. Posted onTrustindex verifies that the original source of the review is Google. Posted onTrustindex verifies that the original source of the review is Google. Posted onTrustindex verifies that the original source of the review is Google. Posted onTrustindex verifies that the original source of the review is Google. 車床加工技術高超Posted onTrustindex verifies that the original source of the review is Google. Posted onTrustindex verifies that the original source of the review is Google. Posted onTrustindex verifies that the original source of the review is Google. 技術棒Posted onTrustindex verifies that the original source of the review is Google.